You'll receive the latest updates on new standards, guidelines, and educational resources, as well as expert insights to help enhance your laboratory's performance and compliance.

How CLSI Got the Quality System Essentials (QSEs)

By Lucia M. Berte, MA, MT(ASCP)SBB, DLM, CQA(ASQ)CMQ/OE, Laboratories Made Better!

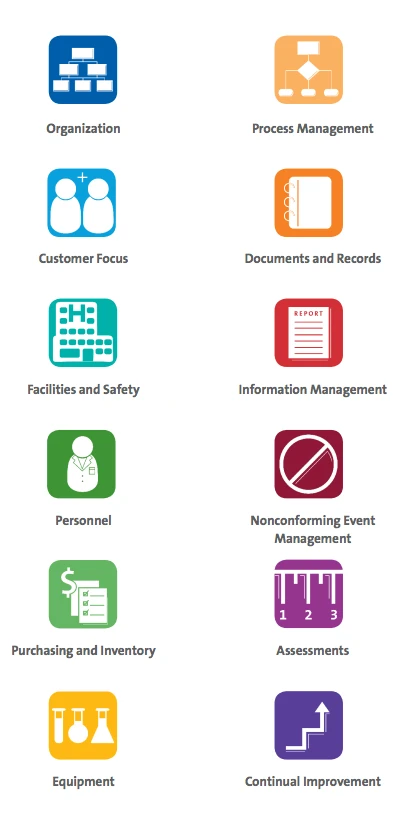

The “Quality System Essentials (QSEs)” have been part of CLSI’s lexicon since it was still NCCLS—and now for almost 20 years—but the phrase was not invented by this organization’s volunteers. In the mid-1990s, when the U.S. Food and Drug Administration started citing blood banks and transfusion services for violating the good manufacturing practice (GMP) regulation, the American Association of Blood Banks (AABB) began integrating these requirements into their Standards publications and accreditation assessments. GMP requirements include those for facilities, safety, equipment, documents, process controls, records, and a number of other nonexamination laboratory activities. The AABB named these generic topics “Quality System Essentials” (QSEs) and started to require that blood banks and transfusion services implement an operating structure known in manufacturing as a “quality management system” (QMS) to ensure the quality of blood bank testing and services.

By Lucia M. Berte, MA, MT(ASCP)SBB, DLM, CQA(ASQ)CMQ/OE, Laboratories Made Better!

The “Quality System Essentials (QSEs)” have been part of CLSI’s lexicon since it was still NCCLS—and now for almost 20 years—but the phrase was not invented by this organization’s volunteers. In the mid-1990s, when the U.S. Food and Drug Administration started citing blood banks and transfusion services for violating the good manufacturing practice (GMP) regulation, the American Association of Blood Banks (AABB) began integrating these requirements into their Standards publications and accreditation assessments. GMP requirements include those for facilities, safety, equipment, documents, process controls, records, and a number of other nonexamination laboratory activities. The AABB named these generic topics “Quality System Essentials” (QSEs) and started to require that blood banks and transfusion services implement an operating structure known in manufacturing as a “quality management system” (QMS) to ensure the quality of blood bank testing and services.

At that time, a number of us were AABB members and also were or had been medical laboratory, blood bank, or transfusion service managers or quality officers. We remarked to each other and in public that the generic QSE topics also applied to the medical laboratory disciplines of chemistry, hematology, microbiology, and anatomic pathology, and not just to laboratory transfusion services and blood banks. A QMS structure of the generic QSEs could be developed for the entire laboratory.

I talked about this issue with then NCCLS Board of Directors member David Nevalainen, PhD, my colleague, co-author, and quality management mentor. He believed the best way to bring the QSE concepts to medical laboratories was for NCCLS to develop a guideline for how a laboratory could implement a QMS. Dr. Nevalainen met resistance from NCCLS’s Board because some members believed that since laboratories already practiced quality control and quality assurance, adopting the QSEs in a laboratory-wide QMS was neither needed nor required. Dave persisted in explaining to the Board the benefits of having a simple quality management structure for the entire laboratory, and together we presented an explanation of the QMS model and how it worked. The Board eventually agreed to convene Subcommittee on GP26, A Quality System Model for Healthcare, on which Dave and I served from 1997 to 1999.

CLSI GP26, now CLSI QMS01, is currently in its 4th edition, with the 5th edition to publish in 2018. Over the years, CLSI volunteers have developed a library of over 20 quality management guidance documents, products, and an online learning course to help laboratories implement an effective QMS.

“CLSI” and “QSEs” are strongly linked on the world stage. CLSI’s Global Health Program has been using the QMS model as the basic outline for helping laboratories in developing economies to improve the quality of testing and services and achieve accreditation to the ISO 15189 international medical laboratory standard. Laboratories worldwide now use well-developed QSE principles and processes to improve services, meet requirements, and achieve and maintain accreditation.